Cooling System can be classified as the following type:

Open Cycle Cooling Systems

Open systems typically have high flow rates and relatively low temperature rises to limit the rise in temperature in the receiving waters. A typical 350 MW unit would have a flow of some 15000 to 20000 L/s.

Closed Cycle Wet Cooling Systems

In closed cycle wet cooling systems, the waste energy that is rejected by the turbine is transferred to the cooling water system via the condenser. The waste heat in the cooling water is then discharged to the atmosphere by the cooling tower.

Pumps and Pipes in a Cooling Water System

Circulating water pumps supply cooling water at the required flow rate and pressure to the power plant condenser and the plant auxiliary cooling water heat exchangers. These pumps are required to operate economically and reliably over the life of the plant.

Condenser and cooling system

Condense exhaust steam from the steam turbine by rejecting the heat of vaporisation to the cooling water passing through the condenser. The temperature of the condensate determines the pressure in the steam/condensate side of the condenser. Large power plant condensers are usually 'shell and tube' heat exchangers.

General Cooling water Problem:

1. Scaling 2. Corrosion 3. Microbes 4. Fouling

With the proper treatment, a significant proportion of industrial on-site wastewater might be reusable. This can save money in three ways: lower charges for lower water consumption, lower charges for the smaller volume of effluent water discharged and lower energy costs due to the recovery of heat in recycled wastewater. Industrial water treatment and wastewater treatment will vary in cost.

Scaling can be mobile, like a fine silt, or can build up in layers on the metal surfaces of the systems. Scale is a problem because

it insulates and heat exchange becomes less efficient as the scale thickens,

which wastes energy. Scale also narrows pipe widths and therefore increases

the energy used in pumping the water through the pipes.

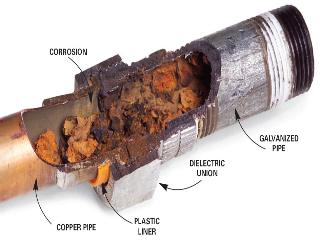

The corrosion products can cause similar problems to scale, but corrosion can also lead to leaks, which in a pressurised system can lead to catastrophic failures.

Microbes can thrive in untreated cooling water, which is warm and sometimes full of organic nutrients, as wet cooling towers are very efficient air scrubbers. Dust, flies, grass, fungal spores and so on collect in the water and create a sort of "microbial soup" if not treated with biocides. Most outbreaks of the deadly Legionnaires' Disease have been traced to unmanaged cooling towers, and the UK has had stringent Health & Safety guidelines concerning cooling tower operations for many years as have had governmental agencies in other countries. Drinking water treatment

Fouling

The deposition of any undesired material on heat transfer surfaces is called fouling. Fouling may significantly impact the thermal and mechanical performance of heat exchangers. Fouling is a dynamic phenomenon which changes with time.

Fouling increases the overall thermal resistance and lowers the overall heat transfer coefficient of heat exchangers. Fouling also impedes fluid flow, accelerates corrosion and increases pressure drop across heat exchangers.

The most common fouling mechanisms are provided below:

Particulate/Sedimentation Fouling

-

Scaling

-

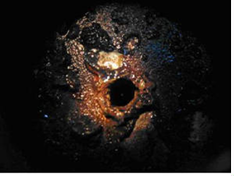

Corrosion

-

Microbes

-

Fouling

|

Corrosion Fouling:

|

Scaling/Crystallization Fouling: |

|

Sedimentation Fouling

|

Chemical Fouling: |

|

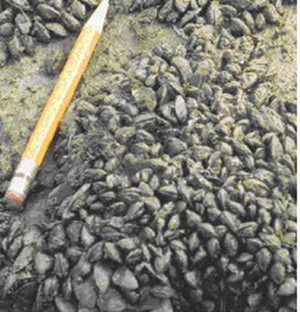

Biological Fouling Occurs when biological organisms grow on heat transfer surfaces. It is a common fouling mechanism where untreated water is used as the coolant. Problems range from algae to other microbes such as barnacles and zebra mussels. |

|

Chemical Fouling: |

Freezing Fouling: |