|

|

|

|

|

|

|

GBR Institute is a new global Bio-science Research Institute combining research faculties, and other famous national wide professors to develop green energy project.

All of the sustainable energy project will base on customer request. Our GBR team will search those available R&D projects which are under academic studying globally. GBR invest each project's pilot plant , research performance and its application capacity.

The potential of algae oil as a fuel source:

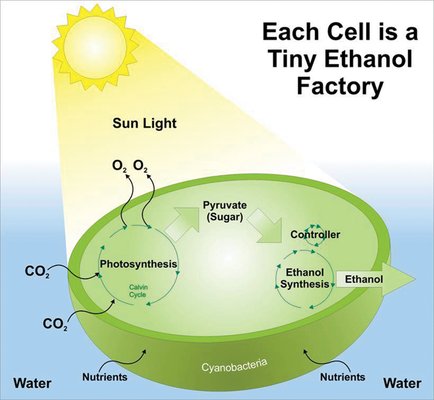

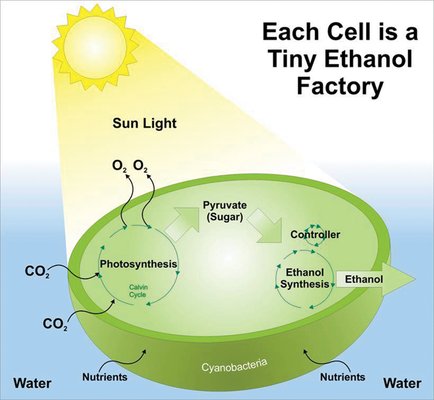

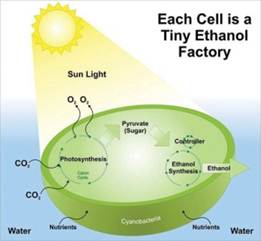

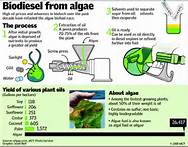

Algae, like corn, soybeans, sugar cane, wood, and other plants, use photosynthesis to convert solar energy into chemical energy. They store this energy in the form of oils, carbohydrates, and proteins.

The annual productivity and oil content of algae is far greater than seed crops.Algae can yield 90,000 liter per hectare. Microalgae contain lipids and fatty acids as membrane components, storage products, metabolites and sources of

energy. Algae can grow anywhere there is enough sunshine and some can grow in saline water.All algae contain proteins, carbohydrates, lipids and nucleic acids in varying proportions. Microalgae can complete an entire growth cycle every few days.

Highest-yielding algae

The algae used in biodiesel production are usually aquatic unicellulargreen algae (Chlorophyceae). Thistype of algae is a photosynthetic eukaryote characterized by high growth rates and high population densities. Under good conditions, green algae can doubleits biomass in less than 24 hours. Green algae can also have high lipid contents, usually over 50%. This high yield is ideal for intensive agriculture and can be an excellent source for biodiesel production

The properties of various fatty esters determine the overall fuel properties of the biodiesel fuel. There is no one strain or species of algae that can be said to be the best in terms of oil yield for biodiesel.

Processes converting algae oil to biodiesel

Photosynthesis is the first step in the conversion of light to chemical energy and ultimately responsible for supporting all biofuel synthetic processes.

|

|

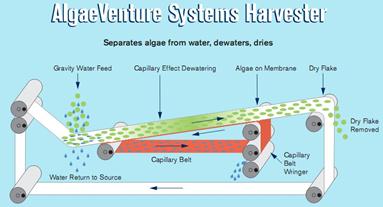

Expeller/Press, solvent extraction with hexane, is a well-known methods to extract oil from algae. A press/expeller extracts 70-75% of the oils out of algae. Using chemicals like Hexane (which are relatively inexpensive) can also be used to extract algal oils. Enzyme extraction process is more efficient than solvent separation methods. Because enzyme extraction process are selective, they provide high purity and product concentrations and can extract nearly 100% of the oils. This liquefied fluid then acts as the solvent in extracting the oil. After oil extraction from algae, the remaining biomass fraction can be used as a high protein feed for livestock. This gives further value to the process and reduces waste.

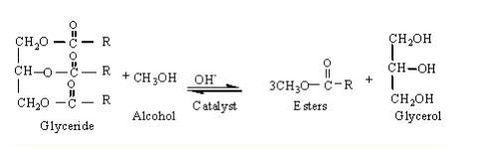

Algal oil is converted into biodiesel through a transesterification process. Oil extracted from the algae is mixed with alcohol and an acid or a base to produce the fatty acid methylesters that makes up the biodiesel.

Transesterification chemical equation

|

|

Advantages of biodiesel from algae oil

Algae oil/algae biofuel: 1) provides rapid growth rates, 2) grows practically anywhere, a high per-acre yield (7-31 times greater than the next best crop—palm oil), 3) algae biofuel is non-toxic, 4) algae biofuel is highly bio-degradable, 5) can reduce carbon emissions based on where it’s grown, 6) algae biomass can be produced at high volumes and this biomass can yield a higher percentage of oil than other sources, 7) algae oil has limited market competition, 8) algae can be cultivated on land, fresh water, or seawater, 9) and can utilize salt and waste water streams, thereby greatly reducing freshwater use.

Algae have the potential of growing in places away from the farmlands and forests, thus minimizing the damages to the ecosystem and food chain supply. Algae can also be grown in sewage and next to power-plant smokestacks, where they can digest the pollutants and deliver the oil.

Disadvantages of biodiesel from algae oil

Biodiesel from algae oil: 1) produces unstable biodiesel with many polyunsaturates, 2) biodiesel performs poorly compared to its mainstream alternative.

Challenges in Agriculture:

The difficulties in efficient biodiesel production from algae are not from the extraction of the oil, but in finding an algal strain with a high lipid content and fast growth rate is not too difficult to harvest, and a cost-effective cultivation system (type of photobioreactor) that is best suited to that strain.

1) too much direct sunlight can kill algae,

2) temperature must be constant,

3) overcrowding will inhibit algae growth,

4) the “waste” oxygen they produce must be continually removed from the water,

5) open algal ponds are subject to evaporation and rainfall, which causes salinity and pH imbalances,

6) local species of algae often overgrow the desired strain.

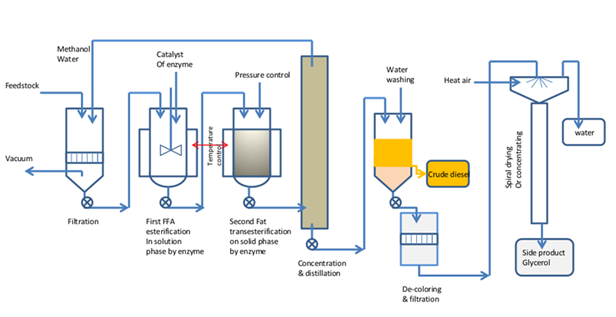

The current enzymatic production application (including the immobilization part) is not a full-scale application as large (industrial scale) as other bio-chemical applications, but results of many lab- and pilot-scale researches show that this process is promising for future applications. We are working to adopt this procedure for the design of a plant with 3 million gallon annually capacity in near future. Research data on Immobilized enzymatic procedure operation cannot be released yet because of concerns on the pending patent held by one of our core members. The current proposed project of algae biodiesel plant for the Chinese customer is using immobilized enzymatic procedure to produce up to one million gallon of diesel fuel with the process schematically shown in the following flowing chart.

Genotech Inc. will continue marketing water treatment, enzyme products and chemicals in Asia whereas GBR will focus on high tech development to integrate those developed R&D products that have been successfully produced using pilot-scale facilities. The production facilities need to be scaled up to full-scale commercial operations.

GBR currently focuses on “Algae biodiesel” and “ Enzyme-Based Treatment for Heavily Contaminated River Dredged Sediment” projects.

Proposed immobilized enzymatic procedure benefits are:

Total Water Management / Water Pond, Lake, River Restoration / Water Filtration / Enzyme wastewater treatmen, laundry, and Dishwash Application / Algae Biodiesel

Algal Production and Harvest for Food, Feed and Biofuels

This patent project are developed through :

(1) Professor, Dr. David Brune and Endowed Chair, Dept. of Agri & Biol.Engr., Clemson University

(2) Assistant Professor, Califonia Polytechnical University, California

(3) Manager, International Network Biofixation of CO2 & GHG Abatement with Microalgae, Walnut Creek, Calif.

This "Algal Systems Applications" are using Controlled Eutrophication Process (CEP) to reach the following target:

- Low-cost, open-air systems

- Biological control for harvest, processing

- Providing environmental services

- Integrated with food, feed, fuel coproduction

Two major project were done for "Integrating Environmental Remediation with By-Product Recovery".

- Clemson/Kent SeaTech

- Salton Sea Restoration & Remediation

Major advantage:

for this Aquaculture / Bioenergy Co-Production process can reach higher Cash-Flow Potential

•Zero emissions •In high efficient harvesting algae District, Our new system can keep the water quality for aquaculture fish or shrimp to produce 20,000-25,000 lbs / acre with zero discharge effluent. •Biomass is 10-20 tons / acre of algae can be produced annually by 5-10 tons / year of fish alternatives, such as Artemia biomass. A one-acre high-rate algal production footprint could support as much as $180,000/yr of aquaculture value, $25,000 of animal feed value with $2,000 to $6,000 of biofuels cash flow. 4 kw/acre of stationary power (as biogas) with 250-500 gallons of liquid fuel/acre-yr (25 -50% of energy required to operate systems) 75-90% of the cash-flow provided by fish or shrimp production, 10-15% from animal feeds, and 5-10% from bioenergy co-production

Pilot plant in Salton Sea

Flow Chart whole system

CEP Algal Sedimentation Belt at Kent

SeaTech in California

high concentration algae

collected wet-dry algae

solar drying algae

2-Ac Freshwater System for Aquaculture @ Clemson

0.25 acre,130,000 gallons, BS reactor =700 gal, 0.5% of system volume

Algal biomass harvest from Partitioned Aquaculture System at Clemson University, S.C.

Algal biomass harvest from Partitioned Aquaculture System at Clemson University, S.C.

Marine shrimp and Fish from harvested pond in Partitioned Aquaculture System at Clemson University, S.C.

Marine shrimp and Fish from harvested pond in Partitioned Aquaculture System at Clemson University, S.C.

Extracted mixed oil

Gravity separation; oil, water and biomass fractions