|

|

|

|

|

|

|

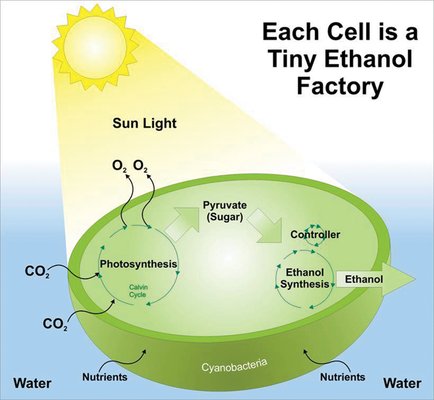

Total Water Management / Water Pond, Lake, River Restoration / Water Filtration / Enzyme wastewater treatmen, laundry, and Dishwash Application / Algae Biodiesel

|

|

|

|

|

|

|

Total Water Management / Water Pond, Lake, River Restoration / Water Filtration / Enzyme wastewater treatmen, laundry, and Dishwash Application / Algae Biodiesel

|

|

|

|

|

|

|

Algal Production and Harvest for Food, Feed and Biofuels

This patent project are developed through :

(1) Professor, Dr. David Brune and Endowed Chair, Dept. of Agri & Biol.Engr., Clemson University

(2) Assistant Professor, Califonia Polytechnical University, California

(3) Manager, International Network Biofixation of CO2 & GHG Abatement with Microalgae, Walnut Creek, Calif.

This "Algal Systems Applications" are using Controlled Eutrophication Process (CEP) to reach the following target:

Two major project were done for "Integrating Environmental Remediation with By-Product Recovery".

Major advantage:

for this Aquaculture / Bioenergy Co-Production process can reach higher Cash-Flow Potential

| •Zero emissions •In high efficient harvesting algae District, Our new system can keep the water quality for aquaculture fish or shrimp to produce 20,000-25,000 lbs / acre with zero discharge effluent. •Biomass is 10-20 tons / acre of algae can be produced annually by 5-10 tons / year of fish alternatives, such as Artemia biomass. |

| A one-acre high-rate algal production footprint could support as much as $180,000/yr of aquaculture value, $25,000 of animal feed value with $2,000 to $6,000 of biofuels cash flow. |

| 4 kw/acre of stationary power (as biogas) with 250-500 gallons of liquid fuel/acre-yr (25 -50% of energy required to operate systems) 75-90% of the cash-flow provided by fish or shrimp production, 10-15% from animal feeds, and 5-10% from bioenergy co-production |

Pilot plant in Salton Sea |

|

CEP Algal Sedimentation Belt at Kent |

high concentration algae |

collected wet-dry algae |

solar drying algae |

2-Ac Freshwater System for Aquaculture @ Clemson

|

0.25 acre,130,000 gallons, BS reactor =700 gal, 0.5% of system volume |

|

Algal biomass harvest from Partitioned Aquaculture System at Clemson University, S.C.

|

Algal biomass harvest from Partitioned Aquaculture System at Clemson University, S.C. |

Marine shrimp and Fish from harvested pond in Partitioned Aquaculture System at Clemson University, S.C. |

Marine shrimp and Fish from harvested pond in Partitioned Aquaculture System at Clemson University, S.C. |

Extracted mixed oil

|

Gravity separation; oil, water and biomass fractions |